On this site:

New (dec. 2006) Network site:

|

|

| About the Humming Bird ELC/IGC | |

An Electronic Load Controller (ELC) is used in Micro Hydro schemes with a synchronous generator working as a stand-alone generator. Together with the dump load(s) connected to it, it works as an electrical brake to the generator: It diverts so much power to the dump load(s) that frequency is kept at nominal value. This way, there is no need for turbine with a governor to control generator speed. Governors used to be the most expensive and least reliable component in M.H. schemes in the past. A recent development in Micro Hydro technology is the use of an induction motor (the standard industrial motor) with a suitable set of capacitors as generator, and an Induction Generator Controller (IGC) to keep voltage in check. Due to characteristics of the induction motor with capacitors, also frequency is kept reasonably constant as long as power factor of user loads is above 0.8. In Nepal and Sri Lanka, many of such schemes have been installed and results are positive (see Harvey, Adam e.a. 1993: Micro Hydro design manual, a guide for small-scale water power schemes, IT publications, London). Harvey recommends induction generators for systems below 30 kW capacity as induction generators are cheap, robust, can stand overspeed, require very little maintenance and are available with lower nominal speeds so that transmission ratio can be lower. Only above 30 kW, a synchronous generator would become cheaper than an induction generator with capacitors. However, also below 30 kW, a synchronous generator with ELC might be advantageous because:

Initially, the Humming bird was designed as an ELC. The present design can be modified into an IGC by adding some extra electronics. Existing ELC/IGC designs can be classified in 3 types:

The humming bird ELC has a bit of the first two types. It uses phase angle regulation, but with 2 (or 3) small dump loads instead of one large one. Phase angles for these dump loads are regulated such that if one dump load has a phase angle of 90° (the worst case), the other one is either completely on or completely off. This makes that distortion of generator current is much less than with one large dump load and there is no need to choose a 25 % oversized generator (see type 1 above). Normally, a 5 % oversized generator will do for the 2 dump load version and for the 3 dump load version, the effect of distorted generator current is no longer decisive because the power factor of user load will require a larger generator already. Some other features of the humming bird ELC are:

I think that for succesful M.H. introduction, components should be produced within country as much as possible. This way, the extra costs in terms of money and time for importing components are saved, getting broken components repaired is easier and the scheme as a whole becomes more inspiring because it uses no imported technology. So if organisations or workshops want to set up production of this humming bird design, I would like to help them. For organisations or workshops that need one or a few ELC's for trying them out in a pilot scheme, it is worthwhile to postpone the investments in starting local production until after the pilot phase and data on how much ELC's are needed, are available. Then maybe one of the people who has built an ELC already, could build extra ones for you at a decent price.

|

|

| Humming Bird ELC/IGC: experiences until now | |

De La Salle University, Philippines They bought an ELC of an earlier version from me and installed it 1996. Apparently it broke down 4 times and each time, it was succesfully repaired. Unfortunately, they did not report any details. They had electronics students doing graduate projects on improvements so I guess they wanted to develop their own design. In Hydronet 2-3/96, there was an article: ORETA, Andres and SALAZAR, Godofredo, 1996: Micro hydropower initiatives in Abra, Philippines. The following people have built ELC's / IGC or seriously intend to do so. They all used previous versions of this manual that describe the same design as the present, final version. Mr.

Muhammad Ali Siddiqui and Mr. Muhammad Asim Zaman Khan,

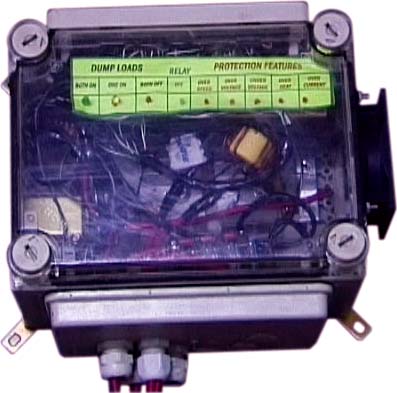

Pakistan Mr. Siddiqui (sorry, no up to date email address available) is student at Mechanical engineering at Ghulam Ishaq Khan Institute of Engineering Sciences and Technology. As his final year project, he designed an M.H. system in cooperation with the Pakistan Council of Appropriate Technology. He contacted me in June '99. Mr. Khan is a student Biomedical Engineering at Sir Syed University of Engineering. He did most of the building work on the ELC, using a PCB provided by me. They could not get all components and most of their questions were about using alternative components. Their first ELC (see picture) was tested using mains voltage in January 2000. By then, apparently Mr. Siddiqui's final year project ended and they could only work on it during holidays. The ELC was tested with a generator set and was scheduled to be installed third week of May 2000. Mr. Khan started building a second ELC for himself. Mr Siddiqui graduated as the best of his year. He planned to go to the USA for an MSc course in Design and Manufacturing. Mr. Kumar Fonseka, Sri Lanka / Canada Mr. Fonseka first contacted me in November '99 and by February 2001, he got his 6-th Micro Hydro project running. All these M.H. projects were equipped with single-phase IGC's. To increase capacity, he used pairs of anti-parallel thyristors (instead of triacs) and got these running without major difficulties. For another project, he built a 3-dump load IGC with high-capacity BTA triacs. End of 2001, mr. Fonseka moved to Canada but he continues to work on M.H. projects in Sri LankaFor more info, see mr. Fonseka's experiences. mail to Mr. Fonseka also built ELC's / IGC's for sale.

A 3-phase ELC was bought by: Mr. Richard Harker, USA Mr. Harker (sorry, no up to date email address available) wants to power his house using a crossflow turbine with an 1.5 kW induction generator installed at a drop in an irrigation canal. His IGC is nearly finished and when it performs well in his tests, he might want to build units for sale to other people. Mr. Harker is an electronics engineering technician and asked only some details about component specifications. Mr. Horacio Drago, Argentina Mr. Drago (sorry, no up to date email address available) builds pico hydro units for battery charging, with a Turgo turbine coupled to an asynchronous generator with the output voltage being rectified. He has ordered 3 Printed Circuit Boards with me. He wanted to start building in the middle of 2000 but that has been postponed. Initially, he was interested in the IGC version. As far as I know, he now wants to build standard ELC's first. More experiences?? If you have used the humming bird design and would like to share your experiences: Send me a report, pictures or the URL of your homepage and I will include it in this page.

|

|

| Swingcat Tidal Turbine | |

The Swingcat vessel (click on it for a full scale view): It sails to and fro like a sheer-ferry on a long anchor cable, driven by the tidal current that generates lift forces on its keels.

|

|

Jan Portegijs Note: To avoid spam, email addresses are hidden by a script. |